Apple is planning to reduce its reliance on human labor in iPhone assembly by up to 50%, a move driven by advancements in automation.

This transition, while aimed at enhancing efficiency and reducing costs, could have significant repercussions on the international labor market, particularly in regions heavily dependent on tech manufacturing jobs.

The Role of International Labor in Apple's Supply Chain

Historically, Apple has relied on international factory workers, particularly at Foxconn, to meet its production timelines. The COVID-19 pandemic in 2020 highlighted the critical importance of these workers when supply chain disruptions caused delays.

The situation repeated in 2022 when riots broke out at Foxconn's main iPhone factory in Zhengzhou, China, over poor working conditions and inadequate pay.

Related Article : Apple Delays Launch of New AI-Powered Features in Europe Due to Regulatory Concerns

Strategic Automation Initiatives

According to a report by The Information, Sabih Khan, Apple's senior vice president of operations, directed managers to reduce the workforce on iPhone assembly lines by up to 50% in the coming years.

To achieve this, the Cupertino titan has revived and heavily invested in automation projects that were previously shelved due to high initial costs. These efforts have already been partially implemented in the production of the iPhone 15.

The Economic Impact of Automation

The shift to automation is expected to lower production costs by reducing labor expenses. However, the high cost of automation technology, which can run into hundreds of millions of dollars, poses a significant barrier. Many of Apple's manufacturing partners are reluctant to make such a substantial investment.

Despite these challenges, Apple's motivation to automate includes minimizing issues associated with human labor, such as health-related absences, demands for better working conditions, and the need for specific accommodations. Additionally, automation can mitigate risks related to geopolitical tensions and trade regulations.

Challenges in Automation Implementation

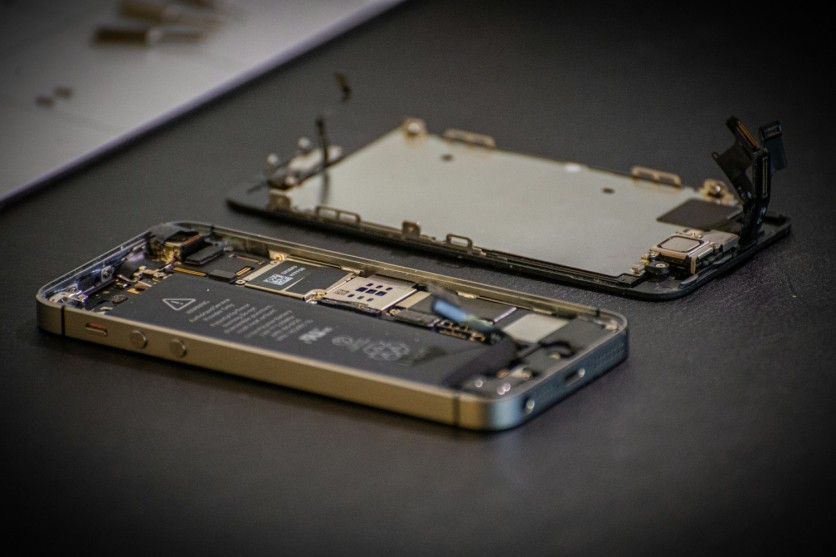

The iPhone maker's transition to automation has not been without issues. Robots used in assembly have struggled with precision tasks, such as placing small components accurately and securing screws with the correct torque. These technical difficulties indicate that while automation promises numerous benefits, it also requires overcoming substantial technical hurdles, per 9to5Mac.

Potential Consequences for China's Labor Market

The impact of automation on China's labor market could be profound. Millions of workers are part of Apple's supply chain, and a significant reduction in the workforce could lead to widespread unemployment and economic instability.

Apple's 2023 supply chain report indicated a decrease in monitored employees from 1.6 million in 2022 to 1.4 million in 2023, a 12.5% reduction and the first decline in over a decade.

Strategic Acquisitions Bolstering Automation

Apple's success in automation has been partly fueled by strategic acquisitions.

Earlier this year, the company acquired Canadian startup DarwinAI, which specializes in inspecting components like printed circuit boards for defects. Moreover, the purchase of Drishti, a startup focused on identifying assembly line bottlenecks in real-time, has further strengthened Apple's automation capabilities.

Future Plans and Adjustments

Apple had planned to automate the installation of buttons and other components for the iPhone 16. However, due to a high defect rate, the company has postponed its workforce reduction targets for another year. This delay highlights the complexities and challenges involved in fully transitioning to an automated production process.

Apple's push toward automation could improve its production game, but it should be noted that it will not be smooth sailing. Although it's projected to reduce cost and increase efficiency, technical issues are inevitable, not to mention the potential economic impact on the labor force.