At a time when the Pentagon is urging America's largest defense manufacturers to accelerate hypersonic weapon production, a small, privately held business in the defense and space industry center of Huntsville, Alabama, is quietly taking big steps to support the call for help. Aerobotix, an AS9100 certified FANUC robotics integrator and metrology company, today officially announced an agreement with Minteq International, Inc. to distribute Minteq's industry-altering FIREXTM RX-2390 Thermal Protection System (TPS) coating for hypersonic flight hardware. Aerobotix will work directly with Minteq's Pennsylvania-based Pyrogenics Group, the global technological leader in high-temperature coatings for military and aerospace applications.

READ ALSO : Agility Robotics 'Delivery Robot' Knocks at Door to Bring Package, Avoiding Face-to-Face Interaction

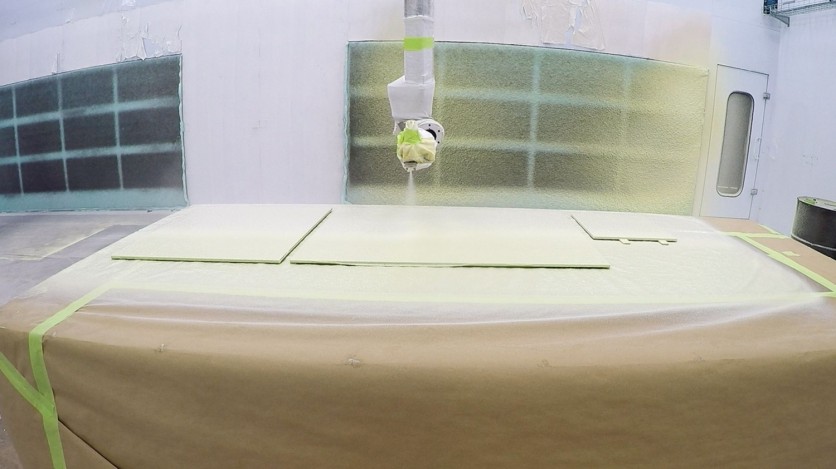

Minteq engaged Aerobotix because of the company's expertise in robotically spraying parts and test panels within extremely tight tolerances for uniformity and thickness of coverage. Aerobotix also has significant prior experience with major primes using the FIREXTM product.

"Our desire was to assist our customers and the U.S. Government in fielding hypersonic missiles and aircraft as quickly as possible," said Kent Pfeifer, Aerobotix's process development manager. "By making the commitment to keep fresh FIREXTM RX-2390 on our shelves, we can immediately assist the major programs by robotically spraying accurate panels and even prototype parts for flight tests. We've been robotically spraying, scanning and sanding shrouds and rockets already, and now - with coating on our shelves - we cut critical weeks in delivery time."

Aerobotix, and the scientists at Minteq, worked together to develop a FIREXTM RX-2390 recipe and a unique robotic paint dispensing system optimized for automation and heavy production. The FIREXTM formulations combine modified epoxy binders with thermally active materials that form cooling gases when exposed to temperatures in excess of 350°F.

Application of TPS coatings requires precision thicknesses control, even distribution of solids, and strong layer-bonding for optimal performance. Minteq notes that Aerobotix's customized robotic application process provides all this, plus the ability to automatically spray-taper the paint thickness in various parts, reducing weight, manufacturing time, and cost.

"Aerobotix is spraying our product so much better than could ever be done by hand," said Mark Breloff, Minteq technical sales manager. "The robot is mixing the coating perfectly, just in time, and applying it so accurately - we are seeing improved performance across the board."

"Aerobotix can scan the part to get the as-built shape, spray to near-net and then use the robot to sand down to the optimal shape and thickness," Breloff added. "Lab results are off the charts with this approach, which, most importantly, allows Minteq to show our customers what RX-2390 is really capable of."

The new agreement with Minteq is a significant enhancement to Aerobotix's new Fully Automated Hypersonic Coating Production System. Designated a "Center of Excellence," the system includes "never been done before" adaptations of high MRL technologies. The facility provides a broad selection of services for preparing and painting hypersonic structures, including automated structured light scanning/projection, automated masking tape application, automated FIREX TM spraying, automated non-contact Terahertz measurement, automated force-controlled sanding, and adaptive robotic machining of coatings.