The use case of self-created nanomaterials is far and wide. Scientists use a process known as bottom-up nanofabrication, or self-assembly, to unearth some incredibly interesting findings in the world of science, such as novel photonic devices and biomaterial development. But to use these nanomaterials to their fullest potential, researchers must first be able to look deep inside them and designate the specific design for intended discoveries,

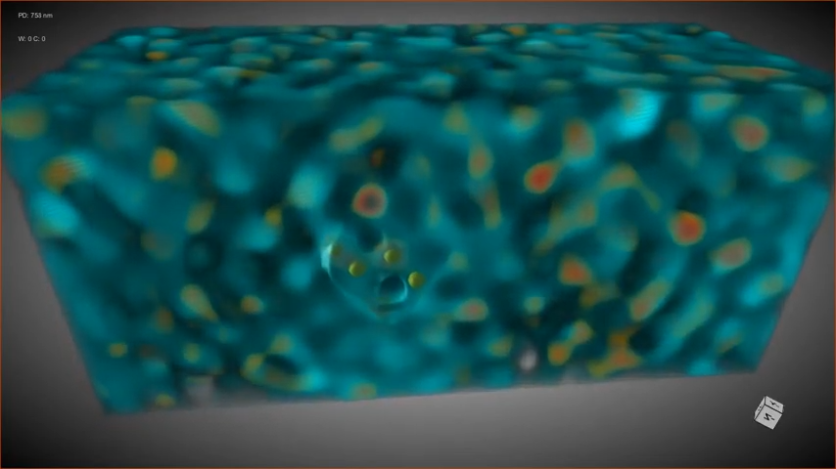

Published in the peer-reviewed journal Science on Apr. 7, a team of researchers under Columbia University and the US Department of Energy's Brookhaven National Laboratory found a way to see into a nanomaterial at a mere seven nanometer resolution. The team utilized sophisticated 3D imaging techniques, best described as a high-resolution x-ray imaging parameter, to then photograph deep within the self-assembled material.

The process is incredibly complex and involves utilizing DNA as a nanomaterial for self-assembly and specific conversion processes so said DNA doesn't get destroyed while being x-ray photographed. The researchers essentially had to take the programmable DNA material and mold it using a template, or a self-defined "blueprint," for the fabrication process to follow. They also needed to then alter the DNA into inorganic materials for its inevitable close-up.

Co-author of the study and a researcher at Brookhaven's Center for Functional Nanomaterials, Oleg Gang, tells of the extreme sophistication behind this process:

"While our DNA-based assembly of nanomaterials offers a tremendous level of control to fine-tune the properties we desire, they don't form perfect structures that correspond fully to the blueprint. Thus, without detailed 3D imaging with single-particle resolution, it is impossible to understand how to design effective self-assembled systems, how to tune the assembly process, and to what degree a material's performance is affected by imperfections."

Related Article: Climate Activists Disrupt Supplies From Three Oil Terminals in the South-East Parts of England

The entire research has been underway for well over five years at this point. One such researcher on the study, Aaron Noam Michelson, calls the initial process itself "only skin deep," in reference to the researcher's surface-level studies on nanomaterials. Eventually, the team had to keep going even further, "we wanted to go deeper to figure out how it worked."

The deeper one goes within these nanomaterials. The more one can unlock its ultimate performance and use case. The group inevitably had to team up with researchers based at the National Synchrotron Light Source II, which houses the Hard X-ray Nanoprobe (HXN) beamline. This tool allows scientists to look deep within particles and materials utilizing ultrabright lights to see nanoscale resolutions.

As one team had to unearth ways of building DNA nanomaterial using inorganic properties, yet another team was attempting to uncover the best functionality provided by the highly dangerous x-ray beamline. The researchers branched off the beamline into two separate strategies. First, the x-ray fluorescence was collected from the sample, these being the light emitted from the sample itself, while also measuring the x-ray's phase contrast as it bolted through the sample.

These two forms of data allowed researchers to see both the foreground and background of the overall project, thus giving them a better sense of the overall scale and a more in-depth picture to work with. Following these new strategies, several months went by as the team had to undergo new 3D software imaging tools and data collated procedures so that this breadth of metadata could be collected without constraint.

"It took my whole Ph.D to get here, but I personally feel very gratified for being part of this collaboration," says Michelson.

While the overall research might be done, a ton of legwork remains, alongside a slew of more advanced studies. With this new information unlocked, researchers hope to discover even more interesting and easier methods for self-assembly in nanomaterials and best-case methods for their functionality. These nanomaterials could be used in a variety of sectors, including even the building of more stable batteries for the future. Thus better design processes for nanoparticle calibration are certainly a must.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.