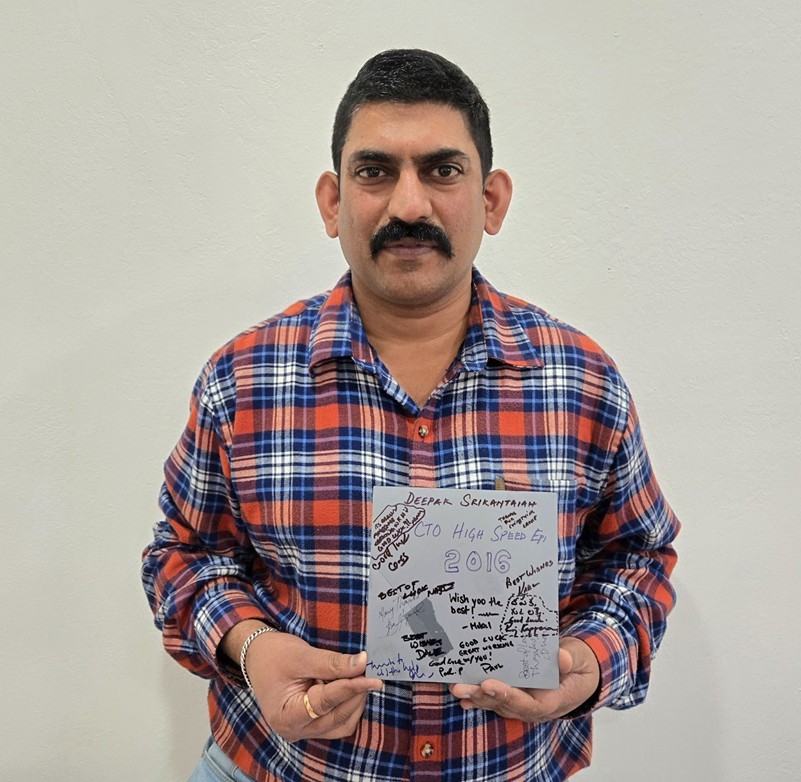

In the precision-driven environment at Applied Materials Inc., senior mechanical engineer Deepak Doddabelavangala Srikantaiah designs the future of semiconductor manufacturing equipment. His expertise focuses on creating systems that control contamination and maintain atomic-scale precision while processing thousands of silicon wafers daily.

Since joining Applied Materials Inc. full-time in March 2014, Deepak Srikantaiah has specialized in semiconductor manufacturing systems. His work culminated in a significant patent (US 10,811,232 B2) for a Multiplate Faceplate for a Processing Chamber, awarded in October 2020. This innovative solution addresses metal contamination in semiconductor chambers while improving coating adhesion.

"Manufacturing at nanometer scales demands absolute cleanliness," Deepak Srikantaiah explains. "Even microscopic contamination can destroy semiconductor components worth millions of dollars." His role combines mechanical precision with materials science to solve these complex manufacturing challenges.

Engineering Background and Technical Development

Deepak D. Srikantaiah built his expertise through positions at major technology companies. He started at Kennametal Widia India in 2001, designing special-purpose machines. His then worked at Robert Bosch included projects in Australia and Germany, where he refined precision engineering methods. 2007, he joined TCS before moving to Applied Materials as a contractor in 2011.

These positions developed his systematic approach to mechanical design, with each role adding to his precision engineering strategy, from conceptual design to practical implementation. This combination of skills proved essential to meeting semiconductor manufacturing's strict requirements.

Using advanced engineering tools, Deepak Srikantaiah develops mechanical modules. He employs CAD software for 3D modeling, runs Finite Element Analysis tests for structural integrity, and conducts Computational Fluid Dynamics simulations to optimize performance. These analyses ensure systems meet strict manufacturing specifications.

"My work involves thermal management, precision mechanics, and motion control systems. I create comprehensive test plans, analyze performance data, and implement design improvements based on real-world results," he explains, adding how he works through the Teamcenter engineering platform to manage component specifications and collaborate with suppliers.

Manufacturing Solutions, Quality Control, and Technical Leadership

Building on his solid foundation, Deepak Srikantaiah's role has become more complex. It involves independently identifying and troubleshooting complex mechanical issues with minimal supervision and utilizing strong problem-solving skills to resolve challenges efficiently. It requires him to take a technical leadership role or directly execute engineering projects, focusing on developing key suppliers to ensure successful project outcomes.

Deepak Srikantaiah also generates detailed product specifications and coordinates engineering testing, ensuring comprehensive test reports are created. He then reviews them for engineering documentation, specifying and performing complex engineering analysis with limited to no supervision, ensuring that all engineering decisions are well-supported and meet project requirements.

For instance, his multiplate faceplate patent demonstrates Deepak Srikantaiah's practical engineering approach. The design protects surfaces from plasma damage while reducing production costs. Aside from this, his team created specialized ceramic coatings that can withstand extreme temperatures and prevent particle formation.

In addition to overseeing prototype development and testing in manufacturing environments, Deepak Srikantaiah also designed specialized maintenance access points that preserve clean room conditions. These systems maintain temperature stability across two-meter processing chambers while preventing contamination.

He works with cross-functional teams at Applied Materials, including procurement, program management, and assembly groups. He reviews Engineering Technology papers for Applied Materials, establishes technical standards, develops technical specifications for suppliers, and guides offshore teams, ensuring consistent manufacturing quality across all projects as a senior technical expert.

Current Projects and Technical Advancement

Deepak Srikantaiah's recent work focuses on improving manufacturing efficiency through enhanced thermal management and motion control systems. His designs enable manufacturers to produce increasingly complex semiconductor components while maintaining reliability and cost-effectiveness.

He is responsible for specifying, designing, or modifying engineering layouts, schematics, and detailed drawings for projects of substantial complexity, ensuring that all specifications meet technical and functional requirements. The task also involves collaboration with internal teams and external customers, addressing various mechanical issues and offering tailored solutions for specific projects.

Deepak Srikantaiah applies his expertise in GD&T (Geometric Dimensioning and Tolerancing), material selection, and thermodynamics to solve emerging manufacturing challenges. He entails designing, developing, and implementing custom mechanical tooling, fixturing, and related processes that facilitate the handling, assembly, and disassembling of parts, components, sub-assemblies, and final assemblies throughout the product life cycle.

Setting New Standards in the Industry

Deepak Srikantaiah's ongoing projects aim to increase production capacity while maintaining the precise standards of semiconductor manufacturing demands. Through mechanical design and improvements in the manufacturing process, Deepak Srikantaiah helps create production equipment for advanced electronic devices. He has established operational standards and is a technical expert for specialized projects or programs.

His combination of technical knowledge and practical manufacturing experience advances Applied Materials' semiconductor manufacturing capabilities, helping strengthen his department and beyond.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.