A colossal feat of engineering has taken place in the Norwegian Continental Shelf (NCS), extending the life of a vital oil field by 40 years.

Interestingly, this feat was made possible by the largest crane vessel, the semi-submersible crane vessel (SSCV).

Heerema's Mega Crane Installs Jacket for Field Redevelopment

Dutch marine contractor Heerema Marine Contractors played a starring role in this project. They deployed the world's largest crane vessel, a semi-submersible crane vessel (SSCV), to install a massive 90-meter-long jacket on the seabed of the Fenris offshore field located within the Valhall area.

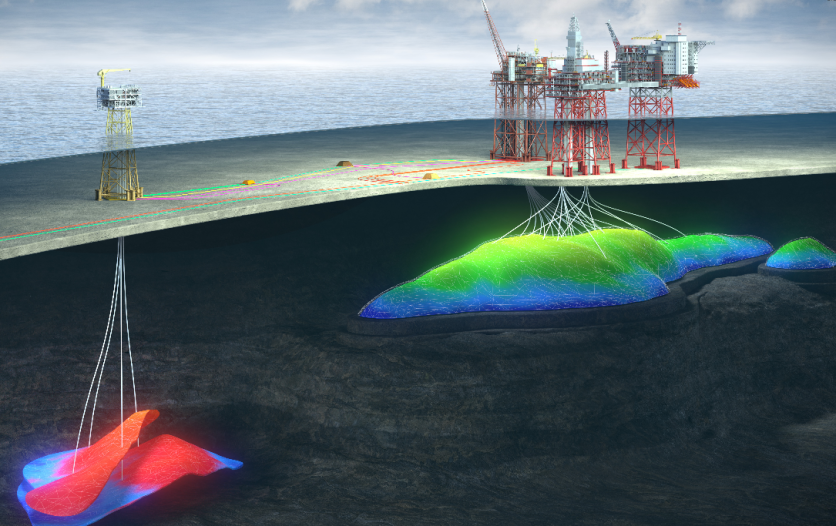

Sanctioned by the Norwegian Ministry of Petroleum and Energy, the Valhall PWP-Fenris project breathes new life into the Valhall oil field, first discovered in 1975. The project targets a reservoir located at a depth of 2,400 meters, unlocking significant untapped potential.

The installed jacket acts as the backbone of the field's extended lifespan. It provides crucial structural support, enabling continued oil extraction for another 40 years. The gigantic SSCV played a vital role in this process, carefully lifting and positioning the jacket onto the seabed.

According to Interesting Engineering, the project officially entered the construction phase in September 2023, when the first steel plate for the Valhall PWP was cut at Aker Solutions' Stord yard.

The plan involves drilling 19 wells, 15 of which will be located at Valhall PWP and the remaining four at Fenris.

Related Article: A Couple of New England Offshore Wind Farms Gets Approval to Operate

Minimizing Emissions with Shore Power

The project prioritizes sustainability. Instead of traditional gas turbines, the Valhall PWP-Fenris development leverages the existing power-from-shore system at Valhall. This smart approach significantly reduces emissions, estimated to be less than 1 kg CO2/boe.

Production from the Fenris field will significantly enhance Valhall's gas processing capacity. This translates to a substantial increase in gas exports from Valhall to Europe via the existing Norpipe pipeline.

The crane vessel will be instrumental in installing additional large offshore structures as part of the project. These include a five-story topside module measuring an impressive 55 meters tall and 54 meters long and weighing approximately 4,800 tonnes.

The jacket itself stands 90 meters tall and is secured by 68-meter piles driven deep into the seabed. Reports indicate that after the grout securing the jacket hardened, an 800-metric-ton PDM (process and utility module) was lifted and welded into place.

The project represents a collaborative effort by industry giants. In January 2024, Worley Rosenberg's facility in Stavanger, Norway, commenced work on the first steel for the utility module destined for the Valhall field center.

"The Valhall PWP will be transported from Worley Rosenberg to Aker Solutions' Stord yard for further hook-up to the production modules before sailing away in summer 2026," Offshore Energy reports.

The massive 16,000-ton Valhall PWP production platform will be constructed at Stord, while the 9,500-ton steel jacket, mirroring the Fenris unmanned platform, will be transported from Verdal.

Aker Solutions: Delivering Subsea Expertise

Aker Solutions plays a key role by providing significant subsea equipment and modifications for the Valhall PWP-Fenris project. ProSep, a renowned provider of produced water solutions and technologies, also contributes to the project.

Jacek Kacperski, ProSep's Sales Manager for Europe, expressed his enthusiasm about supplying the PWT system for the new Valhall platform.

He said the latest contract allows them to implement their leading CTour process onto the new platform's water treatment system. This technology ensures fresh water that passes Norwegian regulations.

The Valhall PWP-Fenris project showcases the power of collaboration and innovation within the oil and gas industry. It's hitting two birds with one stone: it extends the life of a mature field while prioritizing sustainability in the North Sea.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.