Ursa Major, an American aerospace firm, popular for its rocket engines and hypersonic weapons has achieved a significant milestone by completing ground testing of its new hypersonic rocket engine, Draper.

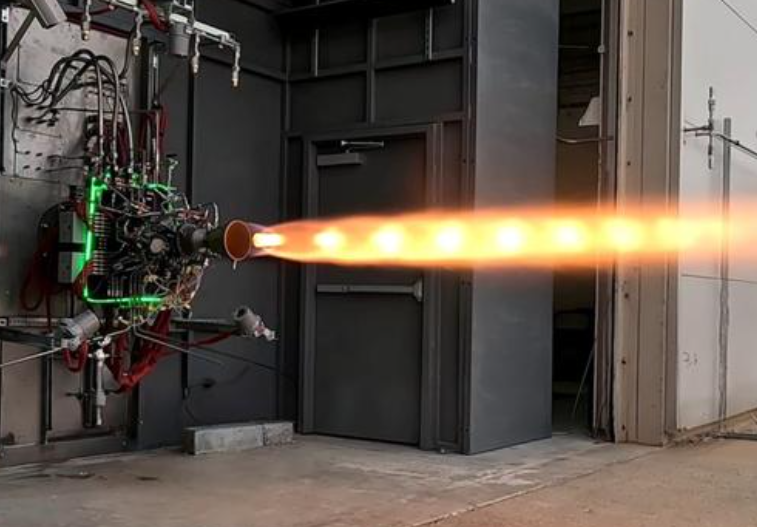

In March, the company successfully conducted over 50 hot-firing tests of the Draper engine prototype at its Berthoud, Colorado facility. Each test firing lasted several seconds, demonstrating the engine's reliability and performance.

Versatile Applications of the Draper Engine

The Draper engine, a liquid propulsion system, is being developed for a variety of applications, including hypersonic defense, in-space propulsion, and on-demand launch capabilities. This 4,000-pound-thrust engine is under development and testing through a contract with the Air Force Research Laboratory (AFRL). The engine's versatile design makes it a crucial component for both military and space exploration missions.

Related Article : Boeing Is Developing Hypersonic Interceptor Prototype Designed to Destroy Incoming Missiles in the Air

Ahead of Schedule Development

Ursa Major announced the Draper engine's development in May of the previous year. Achieving this milestone ahead of schedule underscores the rapid progress of the development program.

Brad Appel, Chief Technology Officer at Ursa Major, expressed excitement about the swift advancement and anticipated the engine's future applications in hypersonics and space operations.

Advanced Propellant Combination

According to Interesting Engineering, Draper engine utilizes a storable hydrogen-peroxide/kerosene propellant combination. Unlike cryogenic fuels that require extremely low temperatures, hydrogen peroxide, and kerosene can be stored at ambient temperatures. This feature simplifies storage and handling, reducing logistical complexity and costs. The engine's ability to store fuels for extended periods makes it ideal for in-space propulsion, such as lunar landers.

Innovative Closed Catalyst Cycle Engine

One of Draper's key features is its "closed catalyst cycle engine." This design allows the engine to operate either entirely on decomposed hydrogen peroxide or on a mixture of hydrogen peroxide and kerosene. This flexibility enhances the engine's fuel efficiency and makes it suitable for precise maneuvering and adjustments in space.

Enhancing Spacecraft Longevity

The Draper engine's efficient thrust profile aims to extend the operational life of satellites and spacecraft. Many satellites fail prematurely due to fuel depletion, even when other systems remain functional. Draper's design addresses this issue, potentially extending missions for more data collection, longer observations, and improved repositioning capabilities.

Future Tests Expected to Come

While the fire tests mark significant progress, the Draper engine will undergo further testing and refinement before its first launch. The engine's applications extend to anti-satellite systems, which are strategic military tools designed to disable or destroy satellites. As global adversaries develop anti-satellite technologies, the demand for advanced defensive systems like Draper's propulsion technology will continue to grow.

"It is this unique design that allows the engine to effectively simulate hypersonic threats and that makes the engine well-equipped to address the critical gap in America's hypersonics capabilities," the company noted.

Leveraging Legacy Technology

The Draper engine builds on the architectural legacy of Ursa Major's Hadley engine, combining the storage capabilities of solid rocket motors with the throttle control of liquid engines. This positions Draper as a crucial component in future space and defense technologies.

Ursa Major's successful ground testing of the Draper engine proves that the US is ahead in military weapons- in various high-stakes applications, from space exploration to national defense.

In other news, Tech Times reported that North Korea released hot air balloons containing hazardous items. Because of this, its neighboring nation South Korea warned its residents not to interact with these dangerous balloons.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.