In biopharmaceutical research, success depends on extracting meaningful insights from meticulously designed experiments. However, complex assay protocols strain laboratory resources, making automation indispensable for efficient high-throughput analysis. Addressing this need for accessible yet adaptable intelligent instruments, Stratedigm's novel A810 Cell Incubator (CI) redefines benchtop incubation.

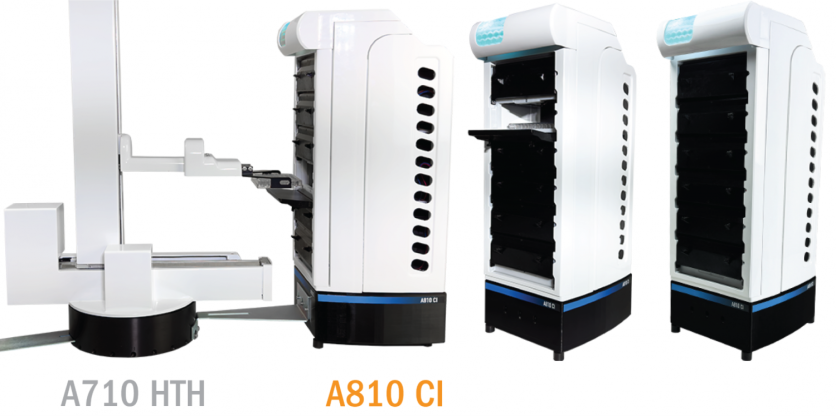

Unlike traditional automated incubators burdened by bulky designs, the sleek A810 CI condenses premium capabilities in an ultra-compact footprint. Occupying under a square foot of bench space, four of these modules integrate seamlessly into Stratedigm's fully automated flow cytometry suite for a complete start-to-finish solution.

At the heart of the A810 lies an architecture with an unwavering focus on design simplicity, performance, and reliability, a core part of Stratedigm's ethos. Nowhere is this more evident than the A810's fully automated architecture, specifically designed for integration with robotics and yet void of any actively moving parts such as servos, stepper motors, solenoids, or other actuation devices. Alongside the novel automation design lies an equally elegant thermal management architecture that relies completely on bi-directional natural convection to ensure an efficient, uniform, and accurate temperature distribution through the internal chamber.

Stratedigm's R&D team architected the A810 to take full advantage of Stratedigm's tightly integrated automation suite by relying on Stratedigm's A710 plate hotel for all robotic operations, including plate insertion and removal along with opening and closing the doors of the incubator. This approach mimics how a human operator's hand would access the A810 and, as a result, eliminates the requirement for redundant actuators. As the first automated incubator without reliance on actively moving parts to move plates or open and close doors, the A810 sets a record for compactness, reliability, and value.

The A810 thermal architecture closely follows its novel robotics design philosophy in terms of performance and simplicity. Powered by three thermoelectric engines coupled to a highly conductive spine, each plate position creates an ultra-stable incubation environment with heating or cooling provided from the top and bottom of each plate via fins that serve as the nest base, delivering consistent temperatures ranging from 8°C to 40°C with better than 0.5°C uniformity. By creating a uniform thermal cavity within the incubator through a conductive spine, the system architecture forgoes the need for internal fans and forced convection, which can often lead to unwanted sample evaporation and thermal variations due to flow dead zones and an inefficient design as the power used by the fans significantly increase the thermal load of the system. This thermal architecture also allows the system to operate within specification, even with one door fully open for an indefinite duration.

Building further upon Stratedigm's portfolio of easy-to-use automation instruments controlled through an intuitive software interface, this incubator offers customizability to accommodate diverse assays. Its small footprint allows existing systems with an A710 plate hotel to be upgraded with incubation capabilities with minimal effort. With up to four A810 CI modules, each operating independently, researchers can set up complex automated assays with an array of incubation conditions from chilled sample storage to heating for staining or culturing.

Critically, each standalone module can house six plates in a wide variety of formats, including standard or deep-well 24, 96, or 384 well plates alongside customized microcentrifuge tube racks compatible with automated liquid handlers. Together with seamless software connectivity that allows commanding the entire automated ecosystem through a common interface, the A810 CI offers the best of two worlds by blending sophistication and simplicity.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.