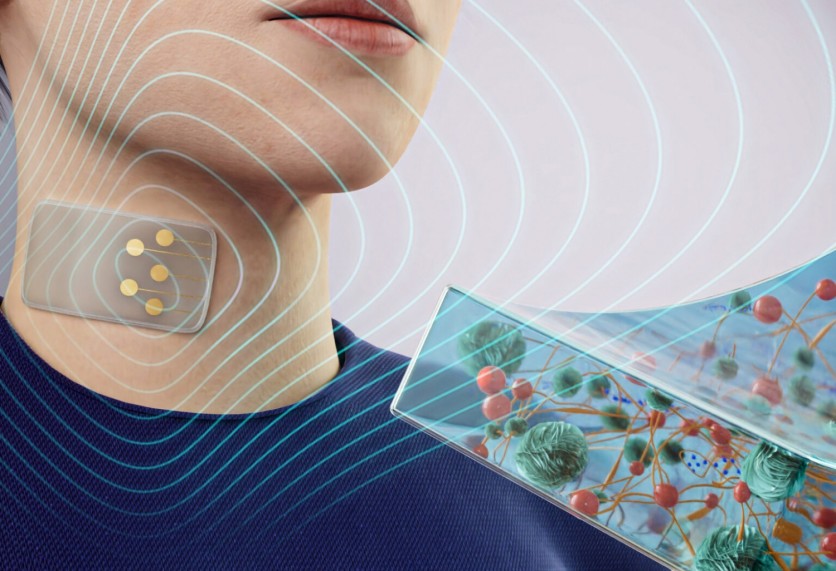

Researchers at Texas A&M University have made strides in developing 3D-printed electronic skin (E-skin) that mimics the flexibility and sensitivity of human skin.

The team created an E-skin that can flex, stretch, and sense like human skin using nanoengineered hydrogels with electronic and thermal biosensing capabilities.

Dr. Akhilesh Gaharwar, professor and director of research for the Department of Biomedical Engineering, highlighted the potential for revolutionizing various industries and enhancing the quality of life for individuals with disabilities.

"The ability to replicate the sense of touch and integrate it into various technologies opens up new possibilities for human-machine interaction and advanced sensory experiences. It can potentially revolutionize industries and improve the quality of life for individuals with disabilities," Gaharwar said in a statement.

All About the E-Skin

The E-skin holds significant potential for diverse applications, particularly in the industry of wearable health devices designed to monitor essential signs like motion, temperature, heart rate, and blood pressure.

This innovative technology can provide users with continuous feedback, assisting them in improving motor skills and coordination. Gaharwar underscored the overarching inspiration guiding the development of E-skin. They aim to establish sophisticated interfaces connecting technology, the human body, and the surrounding environment.

The technology effectively tackles the challenges associated with crafting robust materials that emulate the flexibility of human skin, integrate bioelectrical sensing capabilities, and employ fabrication methods suitable for wearable or implantable devices.

The research team introduced a "triple-crosslinking" strategy to enhance the hydrogel-based system, addressing stiffness concerns and facilitating signal transduction for more seamless interaction with the body's tissues.

3D Printing the E-Skin

Nanoengineered hydrogels assume a pivotal role in the developmental process of E-skin through 3D printing. Their unique ability to reduce viscosity under shear stress enables smoother handling and manipulation. This characteristic proves instrumental in constructing intricate 2D and 3D electronic structures, closely mirroring the complex nature of human skin.

The researchers employed 'atomic defect' in molybdenum disulfide nano-assemblies, a material with imperfections in its atomic structure enabling high electrical conductivity. Additionally, polydopamine nanoparticles were used to enhance the E-skin's adhesion to wet tissue.

Specially crafted molybdenum disulfide nanoparticles served as crosslinkers, providing electrical and thermal conductivity to the E-skin. Drs. Kaivalya Deo and Shounak Roy, the study's lead authors, highlighted the innovative use of molybdenum disulfide as a crucial component in E-skin, emphasizing its potential in healthcare for adhering to dynamic, moist biological surfaces.

As advancements in E-skin technology continue, the potential for transformative applications in robotics, prosthetics, wearable technology, sports and fitness, security systems, and entertainment devices becomes increasingly promising.

The researchers envision a future where E-skin seamlessly integrates with technology, providing enhanced human-machine interaction and sensory experiences.

"This technology represents a breakthrough in flexible wearable skins and holds transformative potential for the future of robotics and human-machine interfaces," the researchers wrote.

The team's findings were published in the journal Advanced Functional Materials.

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.