Tufts University has unveiled a study that not only cuts down the costs of lab-grown meat production but also involves the engineering of bovine muscle stem cells. This approach marks a milestone in making the process of producing lab-grown meat more cost-effective.

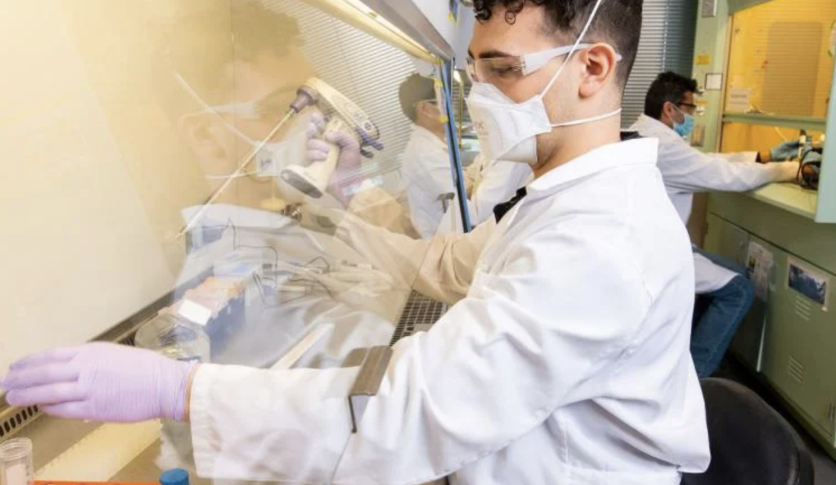

Graduate students conduct research in the Tufts Cellular Agriculture lab.

Slashing Lab-Gown Meat Costs

Researchers at Tufts University Center for Cellular Agriculture (TUCCA) have unveiled a pioneering approach to fostering cellular growth in the field of cellular agriculture. These discoveries have the potential to reduce the costs associated with the process, rendering it more commercially viable on a larger scale.

Cellular agriculture revolutionizes meat production by cultivating animal cells in bioreactors instead of relying on traditional farm animals, as reported by Interesting Engineering.

Recent technological advancements have enhanced the feasibility of this method within the food industry. Growth factors play a crucial role in laboratory experiments and cultivated meat production, aiding cells in their growth and differentiation into diverse mature cell types.

In their recent study, scientists engineered stem cells capable of producing their fibroblast growth factor (FGF). This self-produced FGF catalyzes the growth of skeletal muscle cells, the same type of cells found in popular meat products such as steak or hamburgers.

Andrew Stout, formerly the lead researcher on the project and now serving as the Director of Science at Tufts Cellular Agriculture Commercialization Lab, explained that fibroblast growth factor (FGF) operates more as an instructional cue for cells rather than a nutrient.

As published in its press release, the innovative approach involved engineering bovine muscle stem cells to independently produce these growth factors and activate signaling pathways.

Comparing to Conventional Methods

In contrast to conventional methods in cultivated meat production, where growth factors were externally added to the surrounding liquid or media, EurekAlert reported that this new technique relies on engineered cells that autonomously generate the necessary growth factors.

Typically, growth factors used in cultivated meat are derived from recombinant proteins and are commercially available from industrial suppliers. However, these additives are notably expensive and can contribute up to, or even more than, 90 percent of the production cost.

The need for frequent replenishment of growth factors in cell culture media, due to their short lifespan, poses a challenge in making lab-grown meat an affordable product for consumers. However, a potential solution has emerged through a new technique.

While significant progress has been made in reducing the cost of media, there is still room for optimization to make it suitable for industry use, according to Stout. Despite observing slower growth with the engineered cells, he remains optimistic about overcoming this challenge.

The team's approach revolves around editing and expressing genes already present in muscle cells, focusing on enhancing cell growth for meat production without introducing foreign genes.

This innovative strategy not only addresses the technical aspects but could also simplify the regulatory approval process for the final food product. Regulations are typically more stringent for adding foreign genes than for editing native genes.

Stout envisions the applicability of using FGF for meat growth in various types, including chicken, pork, or fish. Given that almost all muscle cells and other cell types rely on FGF for growth, the choice of optimal growth factors may vary for different species.

Related Article : Lab-Grown Meat More Harmful to Environment Than Real Meat, Claims New Study-Produces 25X More CO2!

![Apple Watch Series 10 [GPS 42mm]](https://d.techtimes.com/en/full/453899/apple-watch-series-10-gps-42mm.jpg?w=184&h=103&f=9fb3c2ea2db928c663d1d2eadbcb3e52)