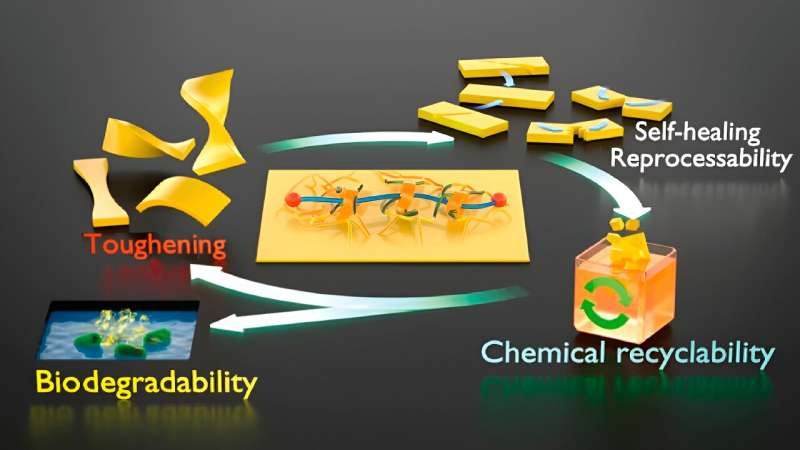

Researchers at the University of Tokyo have unveiled a groundbreaking plastic material, known as VPR, that combines remarkable properties rarely found in a single substance: strength, flexibility, self-healing capabilities, and partial biodegradability.

This material is poised to disrupt the plastic industry and, in doing so, address some of the world's most pressing environmental concerns.

A New Breed of Plastic

In this report shared by Phys.org, we learn that the creation of VPR stemmed from the ingenious combination of an epoxy resin vitrimer and the molecule polyrotaxane.

Vitrimer, a relative newcomer in the world of plastics, is known for its solid and robust qualities at lower temperatures, much like traditional thermoset plastics.

However, unlike their older counterparts, vitrimers have the unique ability to be reshaped multiple times when subjected to higher temperatures, mimicking the traits of thermoplastics. Yet, one of their primary drawbacks is brittleness and limited stretchability. This is where polyrotaxane steps in, elevating the game.

Polyrotaxane, celebrated for its knack for enhancing the toughness of various materials, creates a game-changer. The result is VPR, short for "vitrimer incorporated with polyrotaxane."

It is more than five times as resistant to breaking as the typical epoxy resin vitrimer, as described by Project Assistant Professor Shota Ando from the Graduate School of Frontier Sciences. But that's just the beginning of its astonishing properties.

Self-Healing Material

One of VPR's most astonishing qualities is its ability to self-heal. Imagine a plastic that can recover from damage 15 times faster than its conventional counterparts.

It is a potential game-changer for industries ranging from engineering to medicine. Traditional plastics crack, break, and remain unusable once damaged. VPR, however, can rapidly mend itself, ensuring extended durability and reduced waste.

VPR also has another incredible trick up its sleeve - shape memory. This means that it can quickly regain its original form twice as fast as conventional vitrimers.

Picture a material that not only repairs itself but remembers its original shape. This opens up new possibilities for a wide range of applications, from sustainable fashion to robotics.

Read Also : New Marine Bacteria Capable of 'Eating' Plastic Waste in Oceans Discovered by Researchers

A Step Toward Sustainability

One of the most significant contributions of VPR to the world is its partial biodegradability. Submerging it in seawater for just 30 days results in an astonishing 25% biodegradation, with the polyrotaxane component breaking down into a food source for marine life.

This feature alone could have a profound impact on our efforts to combat plastic pollution. Imagine a plastic that does not accumulate in landfills or pollute our oceans but instead contributes to marine ecosystems.

With the plastic waste crisis looming large, VPR offers a promising solution. Its impressive durability and flexibility make it suitable for a wide range of applications.

From infrastructure materials for roads and bridges to the manufacturing of vehicles, its bond-strengthening capabilities are set to change the game.

The study, "Environment-friendly sustainable thermoset vitrimer-containing polyrotaxane" is published in the journal ACS Materials Letters.

Stay posted here at Tech Times.

Related Article : Scientists Develop the World's Most Water-Repellent Surface Ever

![Apple Watch Series 10 [GPS 42mm]](https://d.techtimes.com/en/full/453899/apple-watch-series-10-gps-42mm.jpg?w=184&h=103&f=9fb3c2ea2db928c663d1d2eadbcb3e52)