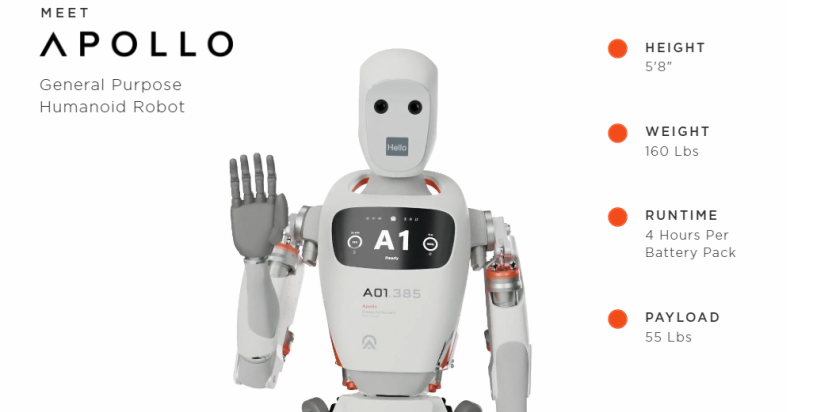

Apptronik, a tech company headquartered in Austin, Texas, has unveiled its latest creation, Apollo, a humanoid robot designed to enter the workforce and quickly contribute to various tasks.

Standing 5 foot 8 inches tall and weighing 160 pounds, Apollo's capabilities rival similar robots in the market. According to Apptronik, Apollo is the world's most capable humanoid robot and the first commercial humanoid robot.

Apptronik's Apollo Humanoid Robot

With a focus on practicality and efficiency, Apollo has been developed to operate on a single swappable battery pack for approximately four hours. This impressive duration sets it apart from other robots, as it can work continuously without frequent recharging.

One of the standout features of Apollo is its lifting capacity, capable of handling up to 55 pounds (25 kg), a notable improvement over competitors like Figure's 01 and Tesla's Optimus robots, both with a 45-pound (20 kg) maximum payload, according to New Atlas.

Apptronik CEO and co-founder Jeff Cardenas emphasized the significance of humanoid robots in addressing physically demanding tasks, particularly in challenging conditions.

He said: "Humanoid robots are not just an answer to this challenge, they are a necessity - and because of our deep robotics lineage, Apollo is uniquely positioned to quite literally step in and make an impact."

In its press release, Apptronik highlighted Apollo's ability to work collaboratively with humans in environments designed for mutual cooperation and incorporates safety features to ensure secure operation alongside people.

Apollo's development drew on Apptronik's extensive experience in robotics, spanning a decade and encompassing over 10 unique robots. The company's expertise ranges from building exoskeletons to enhancing payload capacity in industrial robotic arms.

This diverse background enabled Apptronik to design Apollo as a versatile robot with modular capabilities, adapting to various applications such as bipedal walking, wheeled operation, or stationary tasks.

A significant achievement lies in Apollo's cost-efficient and energy-efficient design, informed by over a decade of refinement and 35 different models of electric actuation systems.

This strategy optimizes performance per cost, facilitating mass production and affordability. Apptronik's proximity to the Texas-Mexico manufacturing corridor contributes to the scalability of producing humanoid robots at an accessible cost, according to the company.

Apollo Robot's Battery System

Apollo's battery system, with swappable four-hour runtimes, ensures uninterrupted operation and efficiency. This design enables Apollo to continue working after a simple battery exchange, eliminating the need for each unit to be charged via a plug-in process.

Initially, Apptronik is concentrating on introducing Apollo to the logistics and manufacturing industries, targeting case and tote handling solutions. However, the company envisions Apollo's applications expanding into various sectors, including construction, oil and gas, electronics production, retail, elder care, and beyond.

Apptronik anticipates Apollo's versatility will allow development partners to innovate and extend its utility to diverse workflows. Apptronik's collaboration with NASA on developing humanoid robots further underscores the significance of Apollo's capabilities.

As a contributor to NASA's goals of enhancing human safety in hazardous environments and expanding humanity's reach in space, Apptronik aims to apply its experience to the commercial market.

"We believe that Apollo is one of the most advanced tools humanity has ever created - how we apply it will change the way that we live and work," said Cardenas.

Related Article : Are Robots Good for Business? New Study Reveals the Answer

![Apple Watch Series 10 [GPS 42mm]](https://d.techtimes.com/en/full/453899/apple-watch-series-10-gps-42mm.jpg?w=184&h=103&f=9fb3c2ea2db928c663d1d2eadbcb3e52)