The U.S. Department of Energy (DOE) has announced its selection of Intel as one of 15 organizations tasked with developing high-performance, energy-efficient cooling solutions for future data centers. The award, announced in May, is part of the COOLERCHIPS program - Cooling Operations Optimized for Leaps in Energy, Reliability, and Carbon Hyperefficiency for Information Processing Systems - supported by DOE's Advanced Research Projects Agency-Energy (ARPA-E).

Intel's project, anticipated to be a three-year agreement with $1.71 million in funding, will enable the continuation of Moore's Law by allowing Intel to add more cores and transistors to its highest performance processors, while managing the heat on future devices.

"Immersion cooling is used for its simplicity, sustainability and ease of upgrades. This proposal will enable two-phase immersion cooling to align with the exponential increase in power expected by processors over the next decade."

-Tejas Shah, principal engineer and lead thermal architect for Intel's Super Compute Platforms Group

Why It Matters:

Data centers account for approximately 2% of total U.S. electricity consumption, while data center cooling can account for up to 40% of data center energy usage overall. The selected projects seek to reduce the energy necessary to cool data centers and lower the operational carbon footprint associated with this critical infrastructure.

To meet the growing demands for computing capacity and performance, future data center processors are expected to require power in excess of 2 kilowatts (kW), which would be challenging to cool with existing technologies. (Today's most powerful chips are fast approaching 1 kW of power use.)

The cooling solutions developed through the program will enhance the capabilities of Intel's processors and those produced through Intel Foundry Services, enable the continuation of Moore's law and further Intel's commitment to energy efficiency and sustainable solutions.

How It Works:

Intel will collaborate with academic and industry leaders to develop its innovative immersion cooling solution. Intel will oversee the research effort, provide thermal test vehicles for evaluation, and define the form factor and constraints for the next-generation processors, including hot spot locations.

Intel's project develops ultra-low-thermal resistance, coral-shaped immersion cooling heat sinks integrated within a 3D vapor chamber cavity to support denser, higher-performance devices. Intel's design will address the challenge of adapting two-phase immersion cooling by optimizing 3D vapor chambers to spread the heat more effectively.

Researchers will 3D-print the novel heat sinks and test the evaporators under a range of operating conditions.

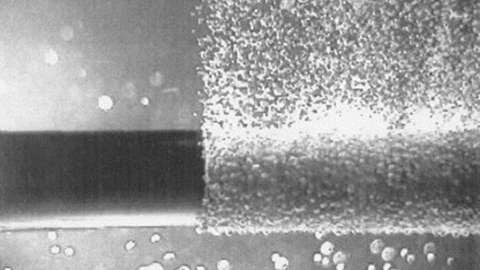

The team will pair the new vapor chamber designs with innovative boiling enhancement coatings that reduce thermal resistance by promoting high nucleation site density. Today, fabricators apply these coatings on a flat surface, but research shows a coral-like heat sink design with internal groove-like features has the highest potential for external heat transfer coefficients with two-phase immersion cooling.

The team will use computational methods to identify the optimal design for the coral-shaped heat sinks. (For comparison, today's heat sinks are typically made of long, parallel ribs.)

Researchers will integrate these innovations into a two-phase immersion cooling system where servers operate in a specially designed sealed tank that uses a non-conductive liquid medium. The heat generated by servers causes the liquid to boil and generates vapor, which in turn goes through a phase change returning it to a liquid state while removing the heat (much like a home air conditioning system).

The team is aiming to improve the capability of the overall two-phase immersion cooling system from 0.025 °C/watt to less than 0.01 °C/watt, or 2.5 times (or more) improvement in efficiency.

![Apple Watch Series 10 [GPS 42mm]](https://d.techtimes.com/en/full/453899/apple-watch-series-10-gps-42mm.jpg?w=184&h=103&f=9fb3c2ea2db928c663d1d2eadbcb3e52)