MIT has unveiled an exciting innovation in the realm of electronic prototyping with the introduction of FlexBoard, a flexible breadboard that revolutionizes the process of designing interactive devices.

In contrast to conventional rigid breadboards, FlexBoard allows designers to rapidly prototype objects with sensors, actuators, and displays on curved and deformable surfaces.

Flexboard's Versatility

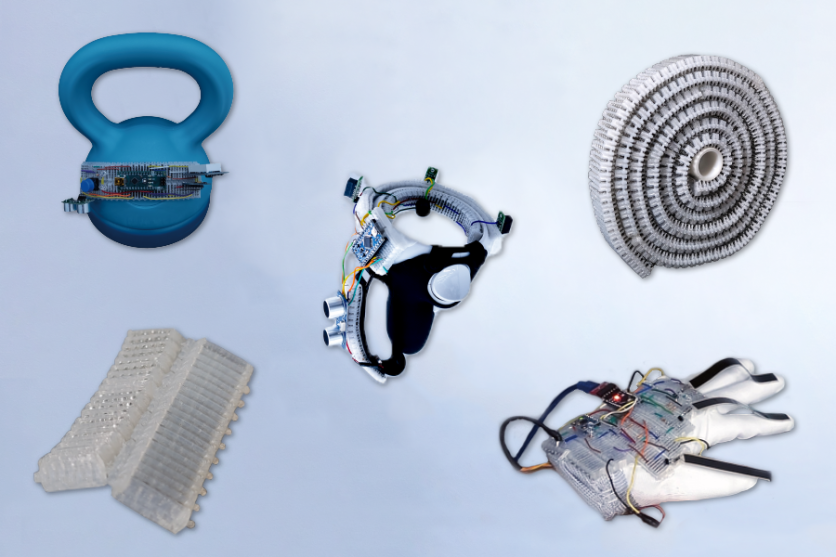

To showcase the versatility of FlexBoard, researchers conducted tests on various items such as kettlebells, video game controllers, and gloves.

The team achieved remarkable results by attaching sensors and displays to the electronic components within the hinges.

For instance, by adding sensors and LEDs to kettlebells, the platform successfully detected users' forms during swing workouts. The display would then indicate whether the exercise was performed correctly or incorrectly, along with the number of repetitions.

The design of FlexBoard utilizes a thin plastic material that connects two identical pieces, enhancing its flexibility. This design incorporates a unique "living hinge pattern," reminiscent of the ones found in condiment bottle caps and plastic disc case spines, effectively holding the electronic components of FlexBoard together.

With the ability to replicate this design using a standard 3D printer, FlexBoards can be fabricated and easily attached to items through sewing, epoxy glue, or Velcro tape.

Michael Wessely, the author of the research, highlights the significance of ubiquitous interactive devices in our modern world. He emphasizes that FlexBoard serves as a versatile and rapid prototyping platform, supporting the design of these devices.

Read Also : MIT's New AI Tech Could Make X-Ray Vision a Reality! Here's How It Could Benefit Vehicles

FlexBoard in VR Gaming?

FlexBoard may also revolutionize virtual reality gaming with collision warning systems in controllers and gesture-capturing gloves. Players wearing VR headsets receive alerts to avoid collisions, while gloves enable intuitive interactions.

FlexBoard's durability allows for repeated bending without damage, attaching seamlessly to curved objects. Its adaptability extends to prototyping, with the ability to cut or combine breadboards for various projects.

For instance, wrapping FlexBoards around a tennis racquet expands sensor capabilities. This streamlined process addresses challenges in early-stage prototyping.

The potential applications of FlexBoard are vast and encompass a wide range of industries, including fitness, gaming, and everyday household items.

However, the MIT team acknowledges that further optimization is necessary to enhance the platform's bendability, durability, and strength via multi-material printing.

Additionally, the current design of each breadboard is specifically tailored for FDM printers, which can limit the length and increase the print time of FlexBoards. The assembly of terminal strips for prototyping bendable objects also presents certain challenges.

"As many researchers have investigated diversifying material properties, we questioned why the breadboard remains rigid," Donghyeon Ko, another author of the work who, said in a statement.

"We wanted to make everyday objects 'breadboard-able' while developing shape-changing interfaces."

The findings of the work were presented at the 2023 CHI Conference on Human Factors in Computing Systems.

Related Article : Bubbles Not Needles: MIT Scientists Create Ultrasonic Patch to Painlessly Deliver Drugs

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.