Los Angeles-based architectural startup Azure is changing the way things are done in the construction industry as they use recycled plastic to 3D print prefab homes. Now, they are selling house models that range from a studio to a two-bedroom houses.

In April, Ross Maguire, the CEO of Azure said, "The construction sector is the largest global consumer of raw materials, responsible for approximately 11 percent of the world's total carbon emissions. Our responsibility to our customers and future generations is to use the most sustainable practices imaginable," as reported by Interesting Engineering.

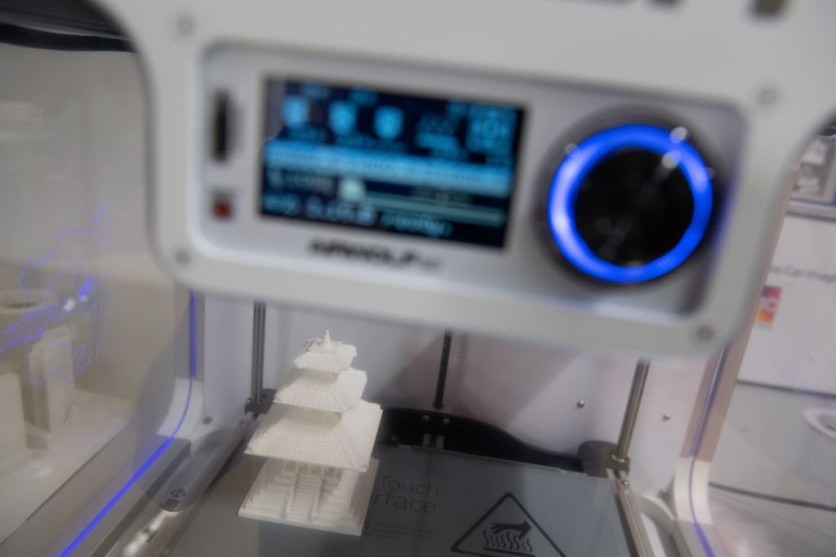

The company also released the world's first 3D printed backyard studio that is made with recycled plastic materials. With that, plastic 3D printed studios and Accessory Dwelling Units (ADUs) are now available for pre-order as Azure speeds up its production line in the Culver City neighborhood in LA.

According to Business Insider, most 3D home builders use mixed or pure concrete to build a home. However, Azure is no longer using them and have opted to build homes through sustainable materials.

The printing materials used by the company are waterproof plastic polymer that is usually found in plastic bottles and packaging food. Aside from taking advantage of 3D printing, Azure also has created a design and process that is completed in only 20 hours.

Compared to traditional construction, the company can produce the whole structural skeleton, exterior sheathing, water control barrier, exterior finish, utilities' passageways, and grounding for interior finishes in a shorter time.

Also Read: This Is The First 3D-Printed Hotel Suite In The World: Yes, It Has A 3D-Printed Jacuzzi

Sustainability of Today's Construction Industry

As the world population and urbanization increases, the construction industry needed to step up their game in building sustainable and low-impact structures.

Aside from using solar panels, the industry has also focused on using recycled and recyclable materials. This has made way for the development and growth of the green home building practice for eco-friendly homes and commercial buildings.

Recently, the construction industry has been driven by the growth of green business practices as the industry is also on the path of providing green housing options for the masses. As a result, the construction industry has seen a boom in the 3D printing industry as more and more people are willing to buy homes that are free of pollution and made from the best of the best sustainable materials.

With the aid of 3D printing, construction industries can now build structures with little or no waste. It allows the structure to be built with unique designs and settings. It also allows them to make use of recycled materials.

The 3D printed homes from Azure might be the answer to all of the concerns on sustainability. Production reduces the material needed and the waste created. This is because the production only requires the plastic polymer.

Related Article: 3D Printing's Contribution to Several Industries: Can It Solve Current Complex Problems?

This article is owned by Tech Times.

Written by: April Fowell

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.