Back in December, Porsche had announced that it had opted to 3D print prototype housing for their electric drives said to be stronger, lighter, and even much quicker for them to manufacture. The said engine-gearbox units that were produced using 3D printing came back even able to pass all of the company's different quality and stress tests without experiencing any issues.

Porsche 3D printing EV parts

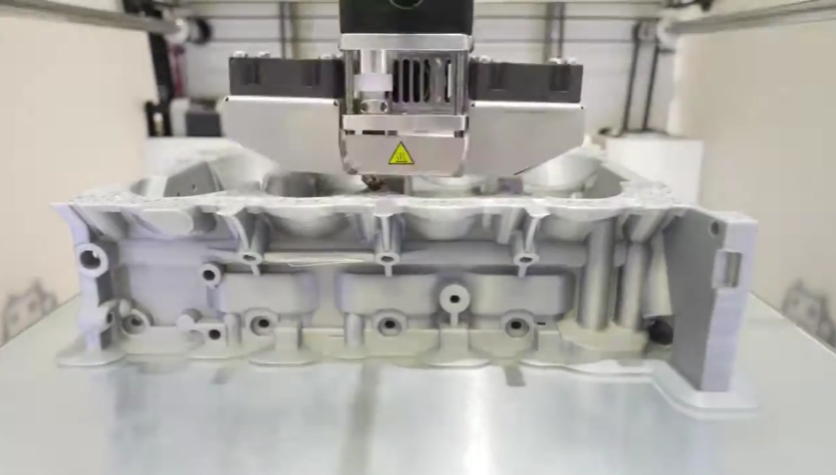

The announcement was released by the official newsroom.porsche online and it stated that Porsche manufactures the housing using a particular 3D printing method that is called laser metal fusion. This would entail a laser beam both melting and heating a powder surface depending on the needed contours. This particular method had allowed Porsche to produce a particular engine gearbox known to be 10% lighter as well as 100% stronger due to the inherent lattice structures.

According to an article by Electrek, another particularly significant upside to manufacturing the parts this way is both the ease and the speed of creating brand new components or even making changes to a few existing ones. For example, an entirely new part can actually be designed and then physically printed in a short matter of time without needing to do certain things like creating the new tooling needed in order to manufacture the specific part.

Porsche Taycan 3D printed parts

Frank Heilfort, a certain project manager in the company's Powertrain Advance Development stated that this provides the company with that additive manufacturing along with all its advantages and is also suitable for both larger and highly-stressed components in certain electric sports cars. Heilfort then even went further saying that electric drives with the said 3D printed parts could also be used some time in the future for certain limited-edition super sports cars.

Implementing these 3D printed parts into the company's EVs just like the Porsche Taycan and also the upcoming all-electric Macan will make a lot of sense when it comes to considering their heavy weight which is due to the car's battery packs. An example of this is the Porsche Taycan 4S which currently weights at about 5,128 pounds. This is said to be about 2,000 pounds much heavier than the Porsche Spyder.

Porsche 3D printing for older models

Having the brand new capability to instead 3D print maybe afew of the said heavier parts of this EV would be able to cut down the curb weight which would potentially squeeze out a little more performance out of the car. Porsche had also stated that there is also potential for the company to begin producing obscure spare parts using the 3D printing technology for other older vehicles that are currently no longer being produced.

The company has also stated that it could also begin to produce certain customization parts that would appeal towards a much more niche customer base even without the huge costs that are typically associated along with such a move. The possibilities that this manufacturing method unlocks could also be considered as truly endless.

Related Article: Porsche Boxster 718 25th Anniversary Limited Edition Car: Specs, Price, and MORE

This article is owned by Tech Times

Written by Urian Buenconsejo

ⓒ 2025 TECHTIMES.com All rights reserved. Do not reproduce without permission.