When you are looking for a provider of electronics manufacturing Company for your devices, you need to be sure that you choose the right one from all the various kinds of providers available, so that you can have a successful and long-term relationship with them.

Here are some points to consider while choosing your electronic manufacturing Company for your devices. Before choosing electronics manufacturing Company for your devices, you want to know that what exactly it is. Electronics manufacturing is a complicated process, and any decision to transfer this practice to an external supplier must be taken with great care.

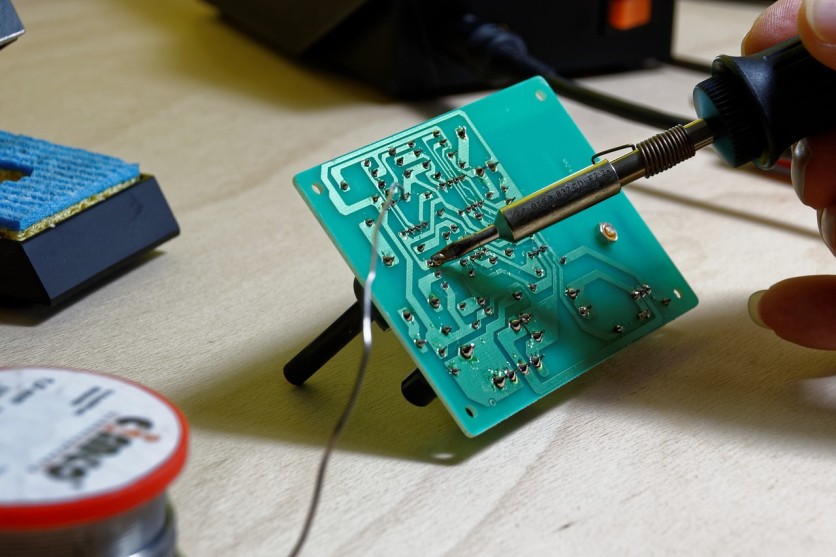

Electronic manufacturing services (EMS) are provided by companies that design, assemble, produce, and test electronic components and printed circuit board (PCB) assemblies for original equipment manufacturers (OEMs). There are lots of reasons why an OEM might choose to outsource its electronics manufacturing. Moreover, the decision can impact the business in the variety of ways, from the people and the premises, through to the connections the OEM holds with their existing customers and suppliers. While the benefits of Company outsourcing for Original Equipment Manufacturers are well documented, there are, of course, risks and concerns. So a successful outsourcing strategy demands a critical assessment of your current positioning and clarity of your future goals and objectives.

Following are the points that you should keep in your mind:

Survey more than one company:

You can start your research for the right electronics manufacturer by checking out their website and discovering as many details as you can. From there, you will want to narrow your list to at least three different manufacturers that you want to survey. This can be a telephone if face-to-face is not possible, but when you meet face-to-face with people, you get a better sense of what it would be like to work with them, and you are capable of telling better that they would be a good fit or not.

Trust your abilities:

Always trust in your abilities from the moment you arrive at the Company, some things tell you so much. If the Company is not a concern with how it projects itself to outside visitors, then maybe that tells you something. You will be relying on them to take off cost and hassle, and this demands a systemic approach to attention to detail - either they have one or they don't.

Do not be afraid to ask questions:

Never hesitate to forget what you wanted to ask. For example, how much experience do they have in manufacturing the component you need? Have they worked on projects similar to yours in the past? What kind of guarantees do they offer? How much do they charge?

Cost is important:

Of course, you have to find out how much the electronics manufacturer charge to create your parts, but you also want to be very clear on what you are getting for that cost. The companies you talk to would likely take some time to give you a very detailed quote, which makes it easier for you to compare what each one is offering for the price. Make sure you know what would happen if any of the parts are faulty. You will want to choose a company that stands behind their product or service and will work with you to make sure you are 100% satisfied with the results.

Check up on credentials:

As part of the interview process, you likely discovered whether or not the electronics manufacturer is appropriately certified to handle your request. If that did not come up, then make sure you ask. Quality accreditations are essential, and so is the manufacturer's on-time-in-full performance. How often do they deliver the full order on time to their customers? It will also give you insight into what the Company's customer service is like.

Design Capabilities Are Paramount:

You should know what type of quality provided by the electronic manufacturing services, and you should ensure that your outsourcer has extensive design resources. You may expect that your project is designed from the ground up, or you may require that the current specification of your board or component is cutting edge, and require a deep-evaluation by an impartial and knowledgeable third party.

Equipment/Technology:

OEM clients expect their manufacturers to have or have access to the equipment and knowledge of the technology needed for their projects. That's one of the reasons they outsource.

In the case of the contract manufacturer, is the equipment current? Have maintenance and calibration schedules been met and documented?

On occasion for a particular application, new equipment may be needed. Be clear about who is paying for that? How long will it take for the equipment to be installed and the personnel to be trained?

Regardless of what's your requirements are the best electronic manufacturing companies that will offer a full series of services, including providing engineering expertise to guarantee that your IP is impeccably designed and to optimize its performance. You can instantly get in touch with PCBA manufacturers to ensure that this is one provider of electronics manufacturing services from China who is qualified to be your partner for life!

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.